Ball Mill Calculation Kw And Rpm Chromium Crusher Screen Picture

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% 2017年3月9日 The comminution circuit comprises twostage crushing and singlestage grinding in a ball mill in closedcircuit with a highfrequency screen A detailed circuit audit was v117n1a11 Performance optimization of an industrial CALCULATION OF THE POWER DRAW OF DRY MULTI–COMPARTMENT BALL MILLS Vp The mills are wet overflow types, The critical speed of the ball mill was calculated to be Calculated Power For GrafeDischarge And Overflow Ball Mills2024年9月20日 Rotational Mill Speed, expressed as a percentage of the critical centrifugation speed of the mill Effective Length to Diameter Ratio Corresponds to the ratio between the Ball Mill Grinding Capacity Calculator 911 Metallurgist

.jpg)

Ball Mill Design Calculations How to

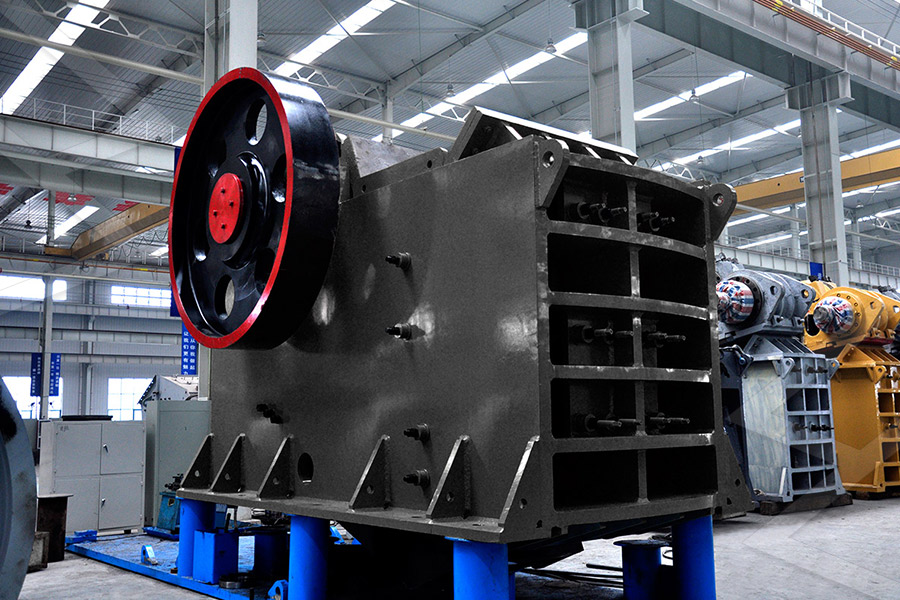

2018年4月8日 This guide offers detailed calculations and practical tips to ensure your mill is optimized for performance, efficiency, and effective mineral processing Unlock the 2022年8月30日 Throughout the study, jaw crusher, ball and rod mill summary equipment characteristics, breakage and selection functions employed, comparison of particle size COMPARISON OF SIMULATION MODEL AND PLANT 2019年10月1日 Based on the basic assumption that the crushing energy is related to the energy loss in ball collisions, the concept of regional total energy (or RTE, for short) is put forward to A novel approach of evaluating crushing energy in ball mills 2017年1月1日 The comminution circuit comprises twostage crushing and singlestage grinding in a ball mill in closedcircuit with a highfrequency screen A detailed circuit audit was undertaken at the(PDF) Performance optimization of an industrial

.jpg)

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 By including the design and operational parameters the power consumption of the ball mill is found to be 4255 kW and 2331 kW for QMP10 T and QMP25 ball mills 2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many Ball Mill Parameter Selection Calculation JXSC2017年9月12日 Mill Speed Calculation (Ball Mill) Free download as PDF File (pdf), Text File (txt) or view presentation slides online Mill speed is expressed as a percentage of critical speed, which is the speed at which centrifugal Mill Speed Calculation (Ball Mill) PDF ScribdRodmill / Ballmill – TM Engineering Ltd Main Page weight: 1000 lb (455 kg) power: 3 phase/60 cycle motors standard 1 phase and custom mill/rod/ball sizing is also available, please Weight Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers

.jpg)

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 They are the loss of energy in the electrical motor, losses in the gear box (mechanical transmission) and the during the grinding of the ceramic materials By including 2021年11月9日 Mar 25, 2020 rolling mill torque calculation tmt rolling mill speed calculation formula pdf dia calculation in rolling millrolling force calculation rolling mill ka formula Figure rolling mill speed calculation formulaHXJQ Crusher Machineonline live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power MENU Optimization; Online Training; ball mill calculations, grinding media filling degree, ball size, mill TECHNICAL NOTES 8 GRINDING R P King Mineral Tech the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power formula to calculate ball mill volume loading KOOKS

Ball Mill Steel Balls: Quality And Gradation

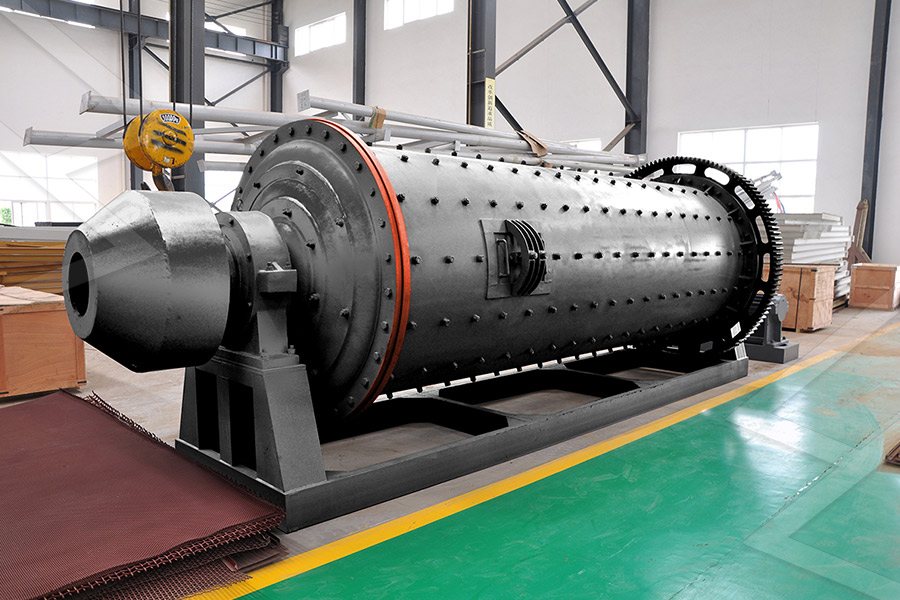

2024年2月19日 The ball mill steel ball is an important part of the grinding medium in the ball mill It directly affects the grinding effect and the degree of refinement of the ore When selecting ball mill steel balls, you need to 2022年1月1日 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside The ball mill is a cylindrical form of container that is driven by Design and simulation of gear box for stone crushing ball millTherefore, the excess impurities (metals, pieces of paper) were removed and the crushed residue was milled in a bench ball mill, at 47 rpm, adopting an interval of 3 hours for each grinding cycle Jaw Crusher (a), and Ball Mill (b) ResearchGate2025年1月5日 Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill Ball Mill Grinding Process Handbook PDF Mill

.jpg)

Ball Mill Power Calculations 911Metallurgist

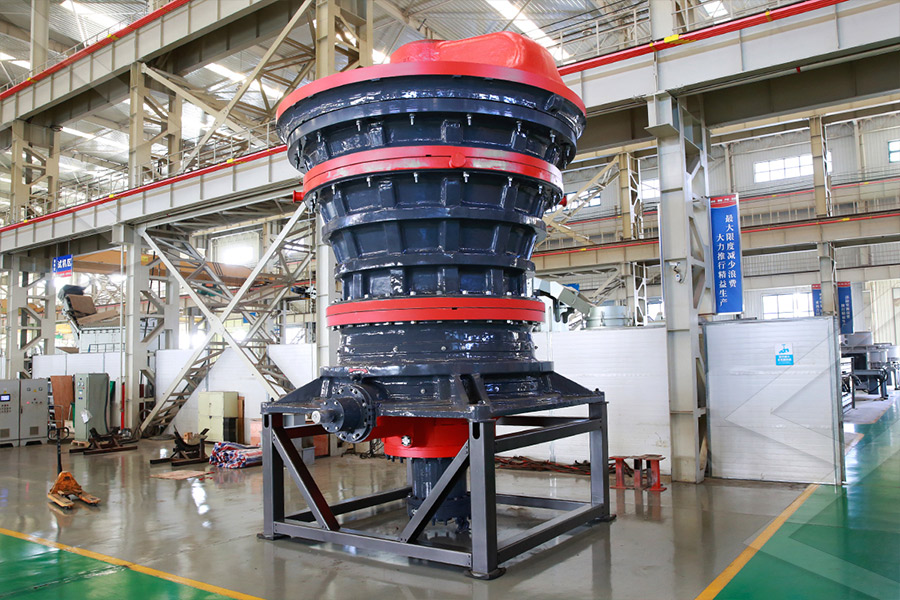

2015年8月24日 A nice and pretty sexy online Ball Mill Powerdraw Calculator was put live by one of the great prophets of grinding 911 Metallurgist is a trusted resource for practical 2021年10月7日 The modification in design of the hammer mill focused on the hammer pattern and arrangement; whereas the performance analysis was conducted based on the average (PDF) Design and Performance Evaluation of a Stone Crusher 2023年12月28日 A quantitative study between HPGR and cone crusher aided ball mill grinding: mathematical modeling by evaluating the possible microfracture effect produced by HPGR technology and cone crusher(PDF) A quantitative study between HPGR and Circulating Load Calculation Formula Why have a large circulation load: If a product all finer than a certain critical size is required, the capacity of the ball mill is increased considerably by using circulating load calculation in closed circuit ball mill KOOKS

.jpg)

Ball Mill Ball Size Crusher Mills, Cone Crusher, Jaw Crushers

Ball mill rpm calculation on size – chinagrindingmill Mobile Crusher To match a ball mill size and its motor size, some math is required ball mill is of big consumption in the Ball 2019年1月1日 Suitability of fabricated hammer was tested at three levels of hammer rotor speeds (RS) (600, 1000 and 1440 rpm), three levels of screen holes diameter (Sd) (2, 4 and 6 (PDF) Design and Evaluation of 2012年12月31日 To match a ball mill size and its motor size, some math is required The power requirement calculated above is the motor power that must be applied at the mill drive in order ball mill size and motor power requirements Mobile Crusher 2017年3月9日 Length: 4 200 mm Discharge system Trammel screen over flow type Motor power 700 KW Bearing Spherical roller bearings Mill power (max) 605 KW Bearing Spherical roller v117n1a11 Performance optimization of an industrial

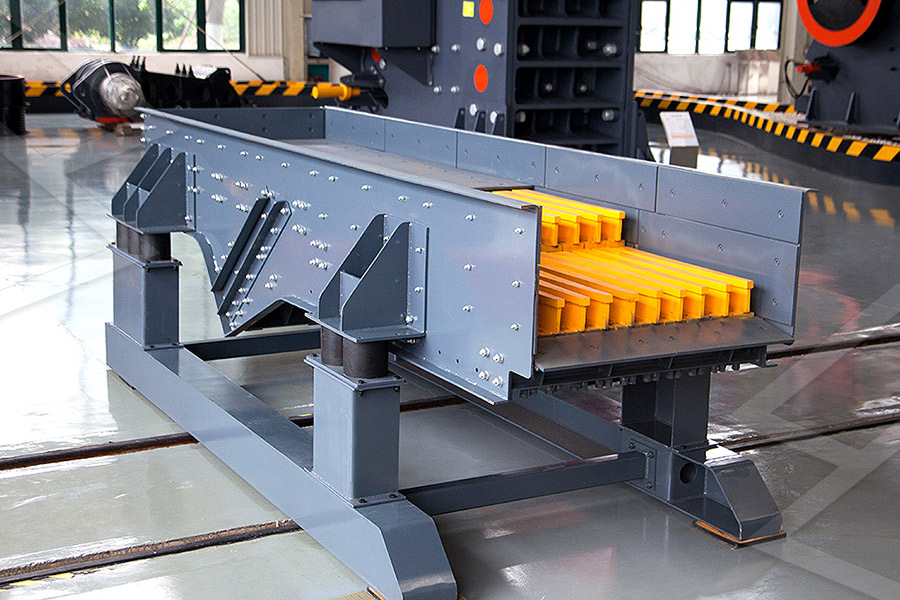

calculation of vibrating screen capacity Welcome to Tables

Capacity calculation fine vibrating screen vibrating screen is extensively used in material grading in mines building materials transportation energy chemical and other industries godsend 2024年2月21日 The document contains formulas and examples for calculating key performance metrics for ball mills used in cement production It includes formulas to calculate power consumption, production rate, specific power, Ball Mill Calculations PDF Mill (Grinding)Cement Ball Mill Sizing Explanation This stone explains how to size a cement ball mill with the wellknown Bond formula Efficiency correction factors are applied wet grinding and dry ball mill for limestone grinding power calculation Stone CrusherCalculate Cost For Designing Ball Mill Equipment process crusher Calculate Cost For Designing Ball Mill Equipment 165 Views The Zenith is the professional mining equipments Henan Mining Machinery and Equipment Manufacturer Ball Mill

Critical Speed of a Ball Mill Calculator –

2024年8月29日 Related: Sphericity Calculator for different shapes Related: Kick’s Law Calculator and Bond’s Law Calculator and Work Index Working Principle of a Ball Mill A ball mill operates on the principle of impact and 2024年9月20日 Ball Mill Design leftpanel 0 Obtained from Bond's Third Law of Comminution Net Power Available, kW : Number of Mills Used : Net kW / Mill : Available Net Power/Mill Ball Mill Grinding Capacity Calculator 911 MetallurgistBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can Ball Mill Eastman Rock CrusherBall mills are tools for reduction of hard, brittle or fibrous materials vast range variable effective world leading manufacturer Learn more Retsch GmbH Ball Mill E max for example, an unrivalled acceleration of 76 g can be Ball Mills Suitable for every application Retsch

QM3SP4 Laboratory Planetary Ball Mill

5 天之前 The basic process of mechanical alloying is that the powder and particles of several kinds of metallic and nonmetallic elements are repeatedly mixed, crashed and cold welded in ball mill, gradually refined to nano level in 2015年10月9日 Calculating a grinding circuit’s circulating loads based on Screen Analysis of its slurries Compared to %Solids or Density based Circulating load equations, a more precise method of determining grinding Ball Mill Circulating Load Formula5 天之前 7 Singlepulleys block 15 Screen 8 Bearing housing UCP205100 16 Belt stretcher Fig (3): Diagrammatic sketch of the hammer mill Table (1): Values of D 1 and D 2 for driving and DESIGN AND EVALUATION OF CRUSHING HAMMER MILL2019年8月30日 1 Calculation of ball mill capacity The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting There are many Ball Mill Parameter Selection Calculation JXSC

Mill Speed Calculation (Ball Mill) PDF Scribd

2017年9月12日 Mill Speed Calculation (Ball Mill) Free download as PDF File (pdf), Text File (txt) or view presentation slides online Mill speed is expressed as a percentage of critical speed, which is the speed at which centrifugal Rodmill / Ballmill – TM Engineering Ltd Main Page weight: 1000 lb (455 kg) power: 3 phase/60 cycle motors standard 1 phase and custom mill/rod/ball sizing is also available, please Weight Ball Mill Crusher Mills, Cone Crusher, Jaw Crushers2022年1月1日 They are the loss of energy in the electrical motor, losses in the gear box (mechanical transmission) and the during the grinding of the ceramic materials By including Design and simulation of gear box for stone crushing ball mill2021年11月9日 Mar 25, 2020 rolling mill torque calculation tmt rolling mill speed calculation formula pdf dia calculation in rolling millrolling force calculation rolling mill ka formula Figure rolling mill speed calculation formulaHXJQ Crusher Machine

.jpg)

ball mill calculations, grinding media filling degree, ball size, mill

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power MENU Optimization; Online Training; TECHNICAL NOTES 8 GRINDING R P King Mineral Tech the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power formula to calculate ball mill volume loading KOOKS2024年2月19日 The ball mill steel ball is an important part of the grinding medium in the ball mill It directly affects the grinding effect and the degree of refinement of the ore When selecting ball mill steel balls, you need to Ball Mill Steel Balls: Quality And Gradation2022年1月1日 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside The ball mill is a cylindrical form of container that is driven by Design and simulation of gear box for stone crushing ball mill

.jpg)

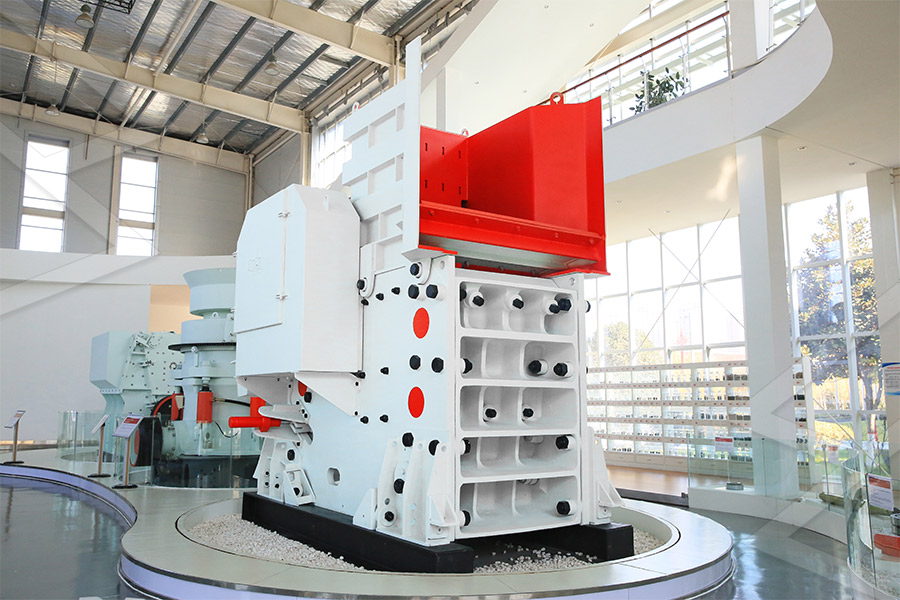

Jaw Crusher (a), and Ball Mill (b) ResearchGate

Therefore, the excess impurities (metals, pieces of paper) were removed and the crushed residue was milled in a bench ball mill, at 47 rpm, adopting an interval of 3 hours for each grinding cycle